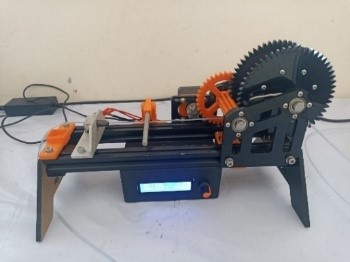

Pengaruh Infill Patern dan Layer Layerthickness terhadap Kekuatan Impact, Bending, dan Densitas menggunakan Filamen dari Botol Plastik Bekas

DOI:

https://doi.org/10.32528/jp.v10i1.3756Keywords:

filamen daur ulang; infill pattern; layer layerthickness; impact; bendingAbstract

Limbah plastik mendorong inovasi bahan alternatif, seperti kunyit, untuk filamen 3D. Penelitian ini menguji kekuatan filamen botol plastik dibanding filamen biasa melalui tes massa jenis, benturan dan lentur, dengan variasi pola infill dan ketebalan lapisan. Hasilnya, filamen botol plastik menunjukkan daya tahan benturan sangat baik, terutama pada pola Gyroid 0,25 mm dan 0,3 mm, bahkan kadang melebihi filamen komersial. Dari sisi berat, filamen botol plastik lebih ringan. Meski daya lenturnya belum menyamai standar industri, peningkatan signifikan terlihat pada variasi tertentu. Secara keseluruhan, filamen botol plastik menjanjikan sebagai solusi 3D printing yang ramah lingkungan dan berkelanjutan, meski masih perlu pengembangan lebih lanjut.

References

[1] M. Mehrpouya, A. Dehghanghadikolaei, B. Fotovvati, A. Vosooghnia, S. S. Emamian, and A. Gisario, “The potential of additive manufacturing in the smart factory industrial 4.0: A review,” Appl. Sci., vol. 9, no. 18, pp. 1–34, 2019, doi: 10.3390/app9183865.

[2] A. D. Nugraha, M. I. Nuryanta, L. Sean, K. Budiman, M. Kusni, and M. A. Muflikhun, “Recent Progress on Natural Fibers Mixed with CFRP and GFRP : Properties , Characteristics , and Failure Behaviour,” Polymers (Basel)., 2022.

[3] C. F. Bănică, A. Sover, and D. C. Anghel, “Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0,” Appl. Sci., vol. 14, no. 21, pp. 1–39, 2024, doi: 10.3390/app14219919.

[4] M. I. Nuryanta et al., “The Interconnection of Carbon Active Addition on Mechanical Green Composite,” Polymers (Basel)., 2023.

[5] Muhammad Gifani Al Qadry, S. D. Dwi, and R. D. Widodo, “Jurnal Inovasi Mesin,” J. Inov. mesin, vol. 4, 2023.

[6] D. Nawang and D. Astuti, “Integrasi Aspek Lingkungan dan Ekonomi dalam Evaluasi Kelayakan Penggunaan Green Packaging dalam Masyarakat,” J. Ekon. Dan Bisnis Digit., vol. 02, no. 03, pp. 1483–1488, 2025.

[7] M. Alaghemandi, “Sustainable Solutions Through Innovative Plastic Waste Recycling Technologies,” Sustain., vol. 16, no. 23, pp. 1–37, 2024, doi: 10.3390/su162310401.

[8] R. Wirantara, M. Syamsiro, and J. Mulyanti, “Pemanfaatan Limbah Plastik PET Sebagai Filamen Printer 3D dengan Metode Pultrusi,” Infotekmesin, vol. 16, no. 01, pp. 166–174, 2025, doi: 10.35970/infotekmesin.v16i1.2467.

[9] K. Formela, M. Kurańska, and M. Barczewski, “Recent Advances in Development of Waste-Based Polymer Materials: A Review,” Polymers (Basel)., vol. 14, no. 5, pp. 1–42, 2022, doi: 10.3390/polym14051050.

[10] Wahyudi, Z. S. Suzen, and Pristiansyah, “Pengaruh Parameter Proses Pencetakan 3D Printing Terhadap Kebulatan Produk Menggunakan Filament PETG,” J. Inov. Teknol. Terap., vol. 03, no. 1, pp. 207–213, 2025.

[11] O. Bouzaglou, O. Golan, and N. Lachman, “Process Design and Parameters Interaction in Material Extrusion 3D Printing: A Review,” Polymers (Basel)., vol. 15, no. 10, pp. 1–35, 2023, doi: 10.3390/polym15102280.

[12] M. Darsin, M. R. Efendi, G. Jatisukamto, H. A. Basuki, and H. Sutjahjono, “Kuat Bending Hasil Cetak 3D printing Berbahan PLA-Kuningan,” J-Proteksion J. Kaji. Ilm. dan Teknol. Tek. Mesin, vol. 4, no. 13, pp. 1–6, 2024, doi: 10.32528/jp.v8i2.1540.

[13] J. Salakory, G. I. Huka, and N. J. M. Nanulaitta, “Pengaruh Variasi Ketinggian Stick Out Pengelasan Gmaw Dan Variasi Sudut Sambungan Pada Kampuh ½ V Baja Karbon Sedang Terhadap Sifat Mekanis,” J. Mech. Eng., vol. 1, no. 3, pp. 144–150, 2023.

[14] L. Judijanto et al., Metodologi Research and Development (Teori dan Penerapan Metodologi RnD), no. June. 2024. [Online]. Available: https://www.researchgate.net/publication/381290945_METODOLOGI_RESEARCH_AND_DEVELOPMENT_Teori_dan_Penerapan_Metodologi_RnD

[15] S. A. Agrawal, “Simplified Measurement of Density of Irregular Shaped Composites Material using Archimedes Principle by Mixing Two Fluids Having Different Densities,” Int. Res. J. Eng. Technol., vol. 8, no. 3, pp. 1005–1009, 2021, [Online]. Available: www.irjet.net

[16] D. A. Roberson, A. R. Torrado Perez, C. M. Shemelya, A. Rivera, E. MacDonald, and R. B. Wicker, “Comparison of stress concentrator fabrication for 3D printed polymeric izod impact test specimens,” Addit. Manuf., vol. 7, pp. 1–11, 2015, doi: 10.1016/j.addma.2015.05.002.

[17] W. F. dos Santos, A. S. L. Rodrigues, I. A. Rodrigues Lopes, F. M. Andrade Pires, S. P. B. Proença, and Z. C. Silveira, “Size effects in 3D-printed polymeric lattices under three-point Bending: Manufacturing, testing, and modelling,” Eur. J. Mech. A/Solids, vol. 114, no. June, p. 105728, 2025, doi: 10.1016/j.euromechsol.2025.105728.

[18] D. Mardiyana, D. I. Sumarno, M. Ali, S. Yudono, and L. A. Islami, “Kajian Kelayakan Sifat Mekanik Produk 3D Printing FDM Berfilamen eFlex TPU-95A untuk Aplikasi Polisi Tidur,” J. Rekayasa Mesin, vol. 19, no. 3, pp. 457–468, 2024.

[19] D. Pezold, M. Wimmer, F. Alfayez, Z. Bashir, and F. Döpper, “Evaluation of Polyethylene Terephthalate Powder in High Speed Sintering,” Polymers (Basel)., vol. 14, no. 10, pp. 1–21, 2022, doi: 10.3390/polym14102095.

[20] S. Guessasma, S. Belhabib, and H. Nouri, “Printability and tensile performance of 3D printed polyethylene terephthalate glycol using fused deposition modelling,” Polymers (Basel)., vol. 11, no. 7, 2019, doi: 10.3390/polym11071220.

[21] M. Wawandaru and M. Fitri, “Perancangan Alat Uji Impak Charpy untuk Material Plastik dengan Takik,” Zo. Mesin, vol. 8, no. 3, pp. 41–48, 2017.

[22] C. F. Popa, M. P. Marghitas, S. V. Galatanu, and L. Marsavina, “Influence of layerthickness on the IZOD impact strength of FDM printed specimens from PLA and PETG,” Procedia Struct. Integr., vol. 41, no. C, pp. 557–563, 2022, doi: 10.1016/j.prostr.2022.05.064.

[23] H. N. Beliu, Y. M. Pellle, and J. U. Jarson, “Analisa kekuatan tarik dan Bending pada komposit widuri - polyester,” J. Lontar, vol. 03, no. 02, pp. 11–20, 2016.

[24] K. ÇAVA and M. ASLAN, “Investigating Printability and Mechanical Performance of 3D Printed Recycled Pet With Pla and Tpu Hybrid Additives,” Int. J. 3D Print. Technol. Digit. Ind., vol. 7, no. 2, pp. 252–258, 2023, doi: 10.46519/ij3dptdi.1324777.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Damas Pasuryan Muhammad

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.